APPLICATIONS

Warm-air-dryers are used for drying and pre-heating solvent-free synthetic granulates.

Advantages here are:

- enlarged plasticizing capacity

- quality improvement

- quality assurance

- improved flow behaviour

Surface humidity at granulate will be achieved with non-hygroscopic synthetics (e.g. PE, PP,PS, etc.) with unfavourable storage, large temperature differences and condensate with high air humidity. A pre-heating is necessary to remove condense humidity. Several machinery can be served by one dryer.

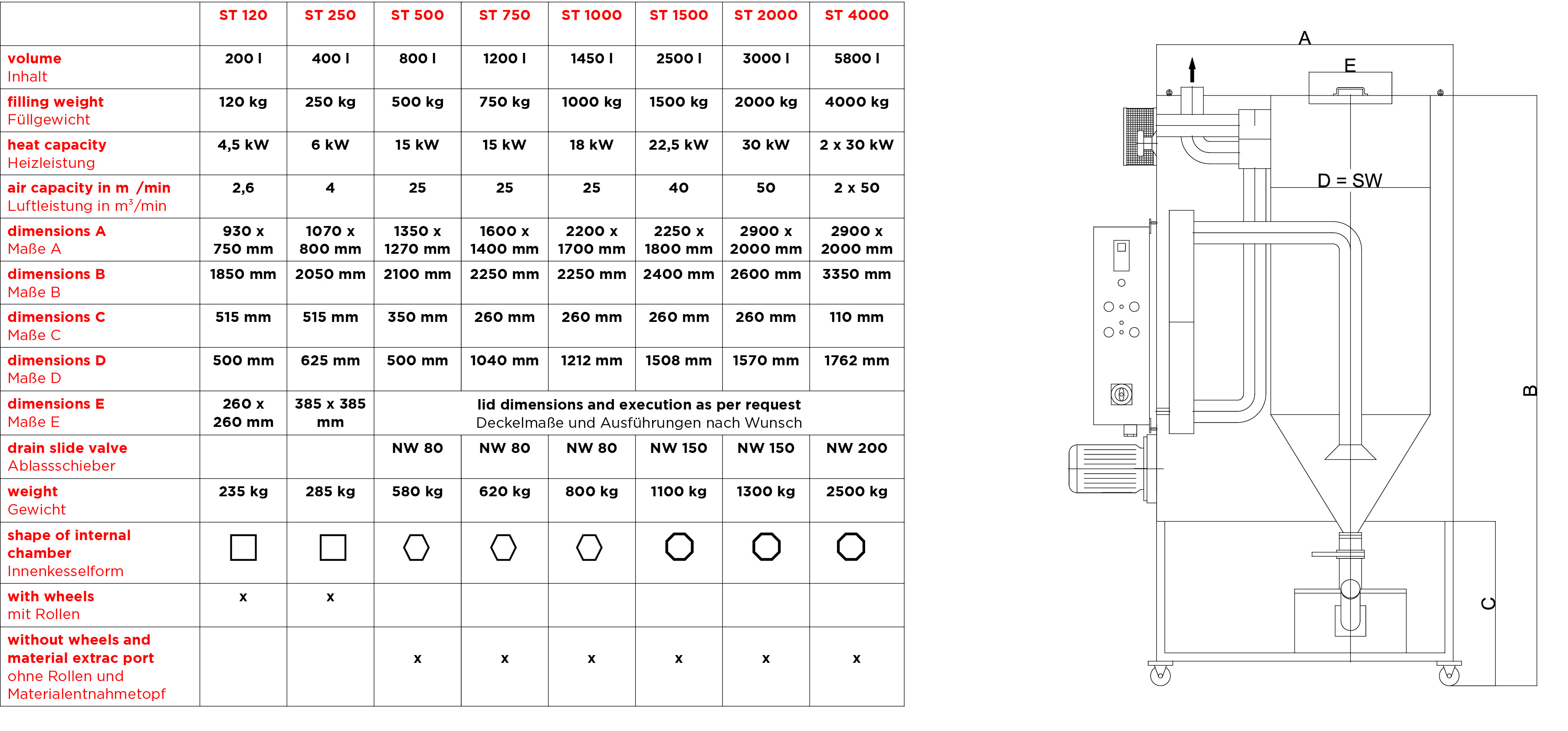

Details

- operating voltage: 3 x 400 Volt, 3-phases/PE 50 Hz

- control voltage: 230 Volt via transformer

- temperature control: industrial electronic Controller, range: 0 up to 160 °C, measuring element: Pt 100

- temperature protection: capillary Thermostat , range: 60 up to 200 °C, heater turn-off and visual signal with over heat

- capacity circuit: conductor

- permanent sound level: < 70 db (A) measured in front of 1 m to the terminal box at 1.6 m height

- thermal safety: class 2 as per IEC 519-2 section 13.4

- outer tank material: sheet steel

- standard outer tank painting: RAL 6011 reseda-green structure

- cleaning port: 400 x 400 mm at side wall

- internal tank material: 1.4541 or 1.4301 stainless steel

- air regulation: adjustable fresh-, circulation and exhaust air slide

- exhaust chimney: Ø 70 mm

- insulation: 60 mm all sides

Options

- voltage and wattage variations

- operating temperature variations

- painting, multi-colour available as per customer request

- labelling and documentation in various languages

- electronic digital clock timer

- operating hours counter

- timer function, turns on after adjusted time (max 99h 59 min) (on request as well off)

- high pressure blowers related to enforced heat capacity for enlarged air flow

- easy-change fine air filter with difference pressure monitor and filter change monitor

- base as per customer requirement

- cut outs at cover for conveyors as per customer requirement

- sockets for conveyors at terminal box

- material withdrawal container/tank as indicated

- interfaces as per customer specification