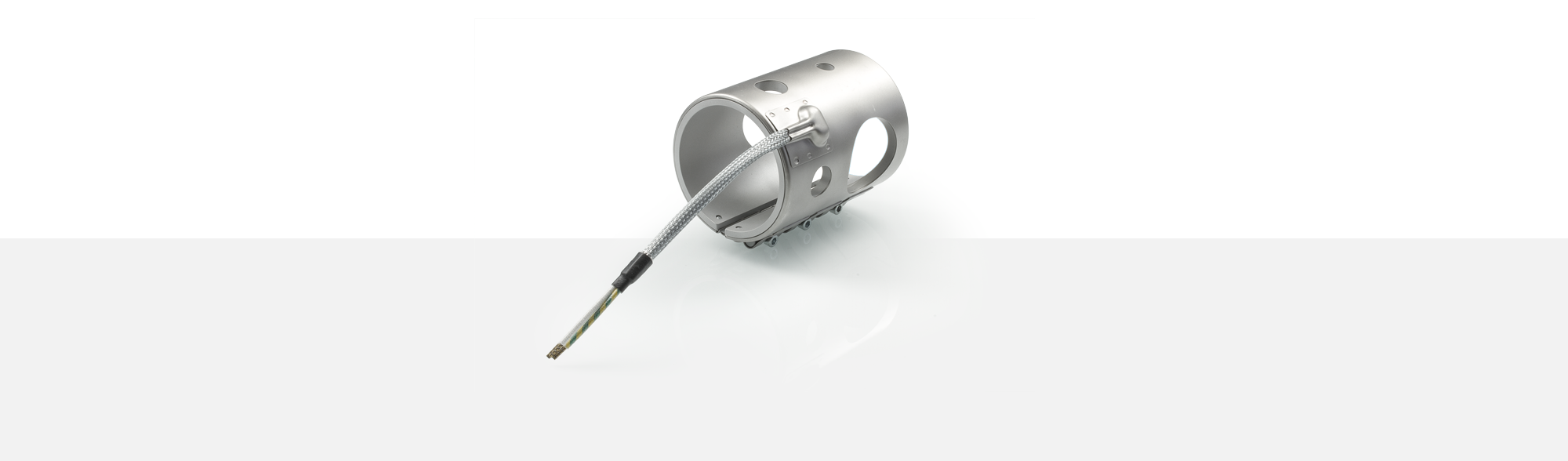

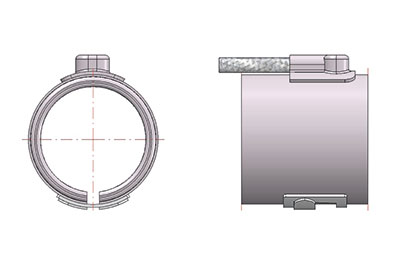

with several holes and cut outs possible

DAK/DMK aluminium/brass compact Nozzle Band Heaters

DAK/DMK aluminium/brass compact Nozzle Band Heaters are used with machinery and tools of the polymer processing industry as well as with other devices with uniform heat demand.

Options

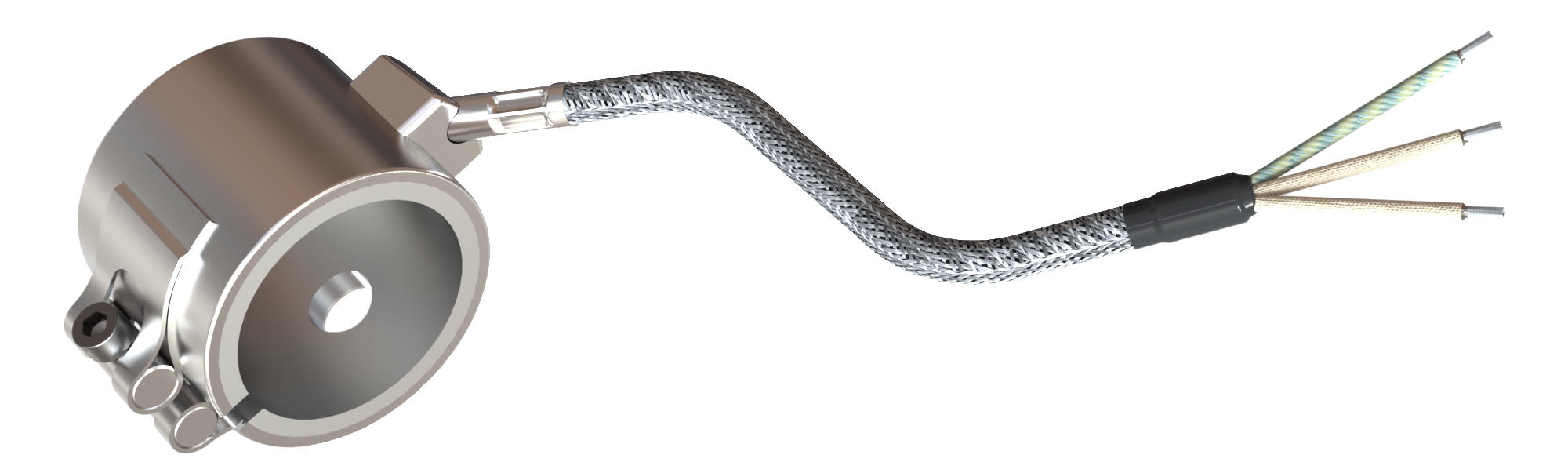

Material

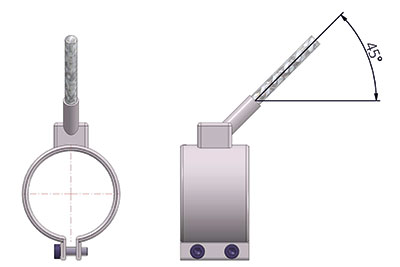

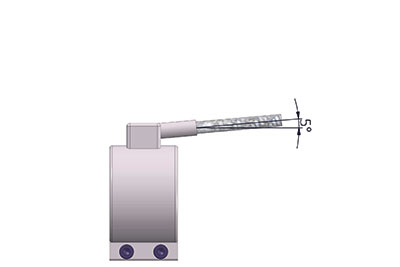

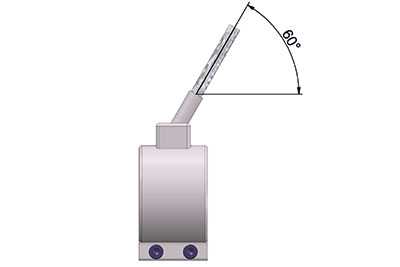

Connection

Connection options

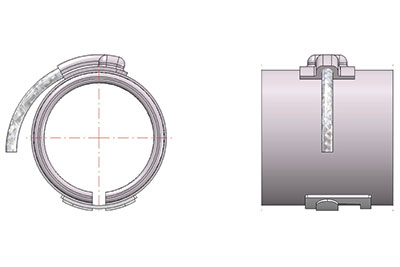

Holes and cut outs

with holes and/or thermocouple bridges

additional cut outs

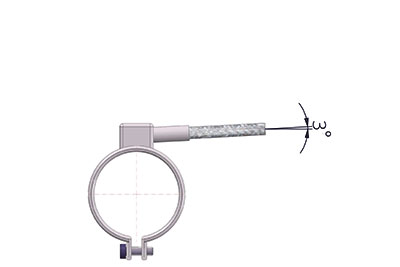

Cable ends

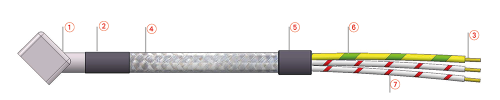

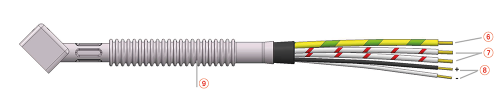

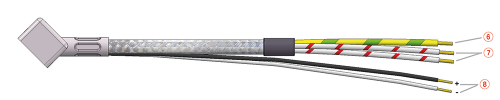

| 1 rigid connection 2 additional protection 3 crimped cable ends 4 metal braided sleeving with colour code 5 heat resistance rubber sleeve |

6 earth protection |

Any

questions?

Find your contact person in one of our locations!